SPC Software

SOFTWARE FOR STATISTICAL PROCESS CONTROL

Manufacturing 0 Defects

- Manufacture with the highest quality at the lowest cost

- Improve productivity and efficiency

- Reduce costs of waste / scrap

- Avoid customer non-conformities

- Comply with quality standards (IATF, ISO, FDA)

+15,000 clients around the world

Forget Paper and Excel!

An optimized process is what all manufacturing companies seek, to achieve the manufacture of their products with the highest quality at the lowest possible cost.

Process variation is the leading cause of scrap, rework, and increased production costs.

So to optimize your processes you need a solution that monitors the process in real time directly from the shop floor and detects risk before problems arise.

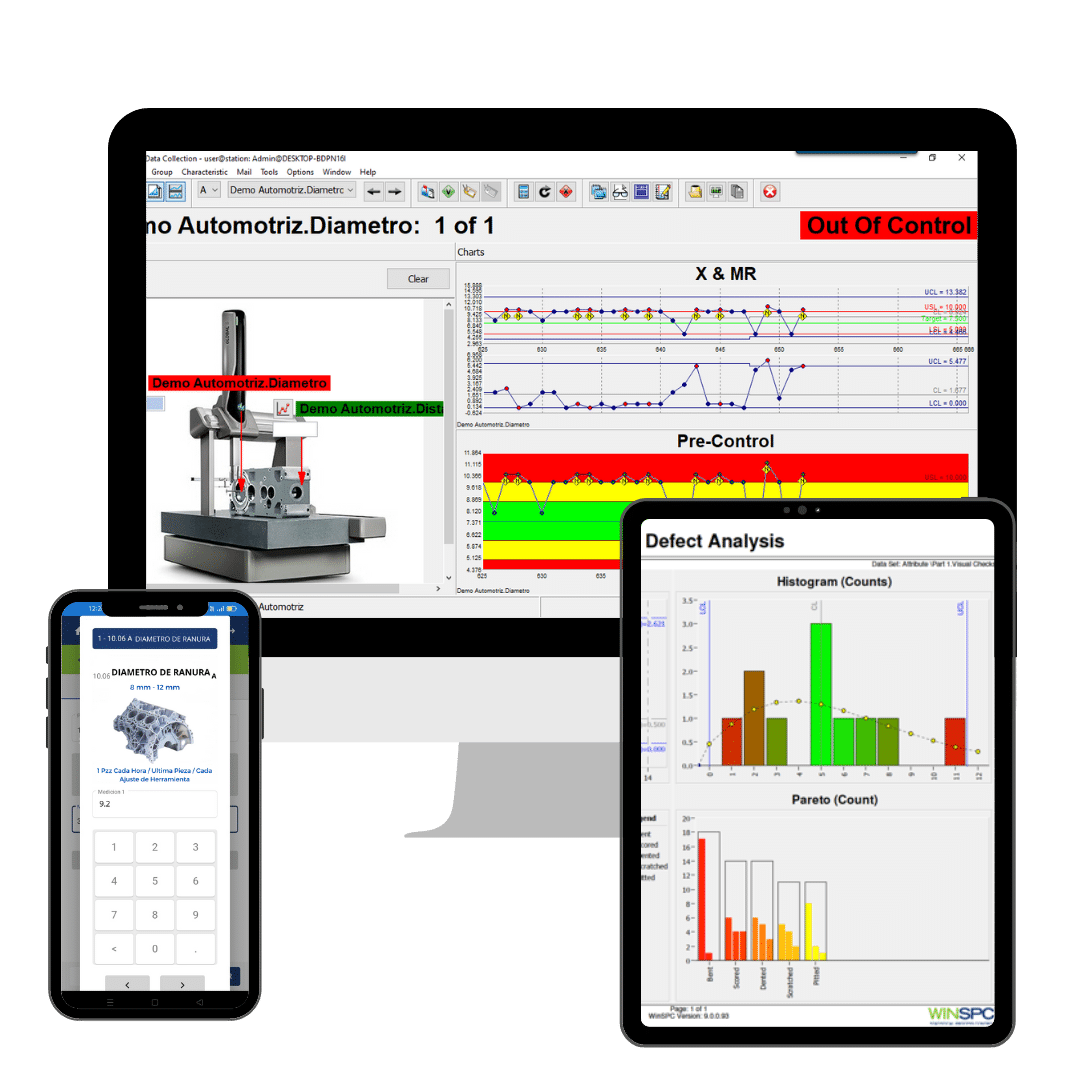

WinSPC is the software-based solution to predictively optimize processes.

Optimize your Processes with SPC software

What can you do with an SPC software?

Data collection

Capture and record the most relevant data of your process, such as variables and attributes, and other important parameters.

Statistic analysis

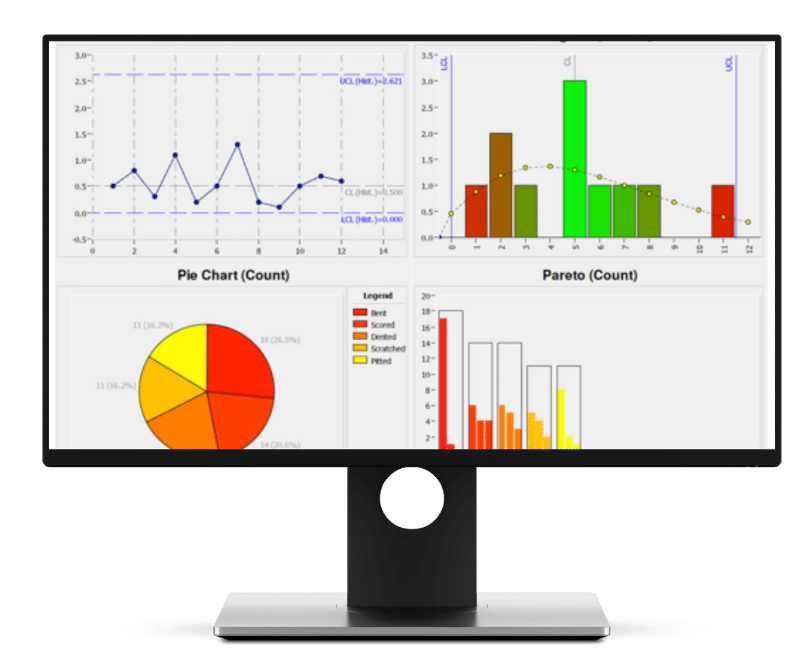

Standard deviation, histograms, control charts, process capacity, etc. Identify patterns and trends.

Control charts

With more than 90 reports preloaded, automated and ready to use, many hours of work are avoided.

Alerts

Configure control limits and set alarm rules to receive notifications when the process deviates.

Trend analysis

Perform long-term trend analysis to identify significant process improvements or changes over time.

Reports

Generate customized reports and graphical presentations of the results for decision making.

Integrations

Easy data transfer and collaboration between different systems and departments (SAP, Oracle, etc.)

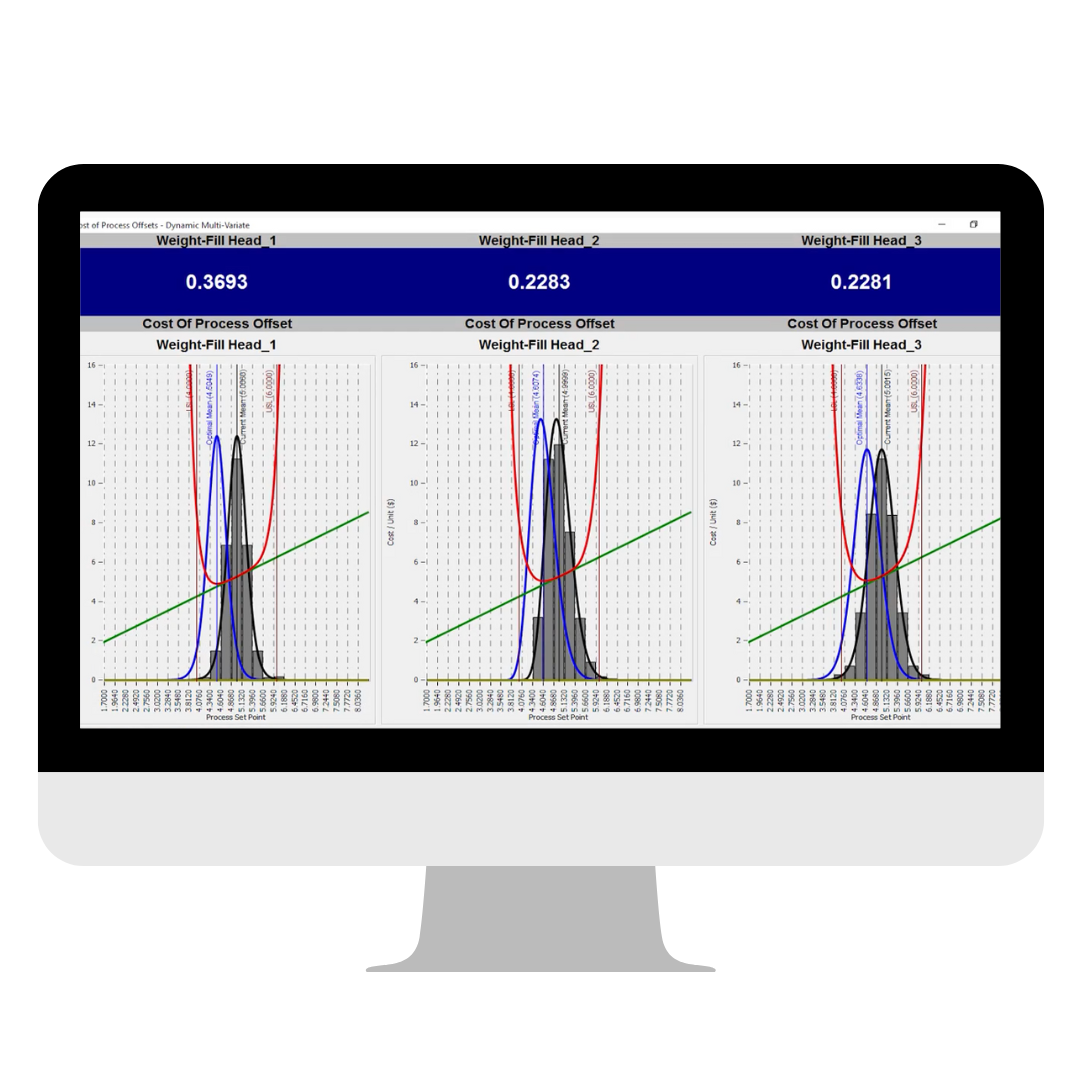

Advanced Analysis

Get deeper analysis of process data and integrate your Business Intelligence solutions.

Software for Statistical Process Control

Streamline automation and real-time data analysis.

As any manufacturer knows, efficiency is key, so quality and process control are of the utmost importance. Real-Time SPC Powered by WINSPC makes quality analysis and improvement easy in one convenient, comprehensive solution, while our real-time monitoring and alerts enable immediate action when quality fluctuates, saving time and money.

Statistical Process Control Software in real time

SPC software supply statistical process control by collecting data in real time and alerting the manufacturer to any results that fall outside the accepted range. This, in turn, helps reduce process variation, improves manufacturing efficiencies, and lowers overall production costs.

Real-Time SPC Powered by WINSPC has the real-time capabilities and reliable analysis you need to take your process monitoring to the next level, all in one convenient, comprehensive solution.

Statistical Process Control – SPC Software

WINSPC (statistical process control) is a solution developed to easily collect and analyze data, allowing you to monitor performance as well as achieve sustainable improvements in quality and profitability.

Commonly known as SPC (Statistical Process Control) in a method to monitor and control through statistical analysis, with the aim of reducing scrap and rework costs, decreasing process variation and saving on material consumption.

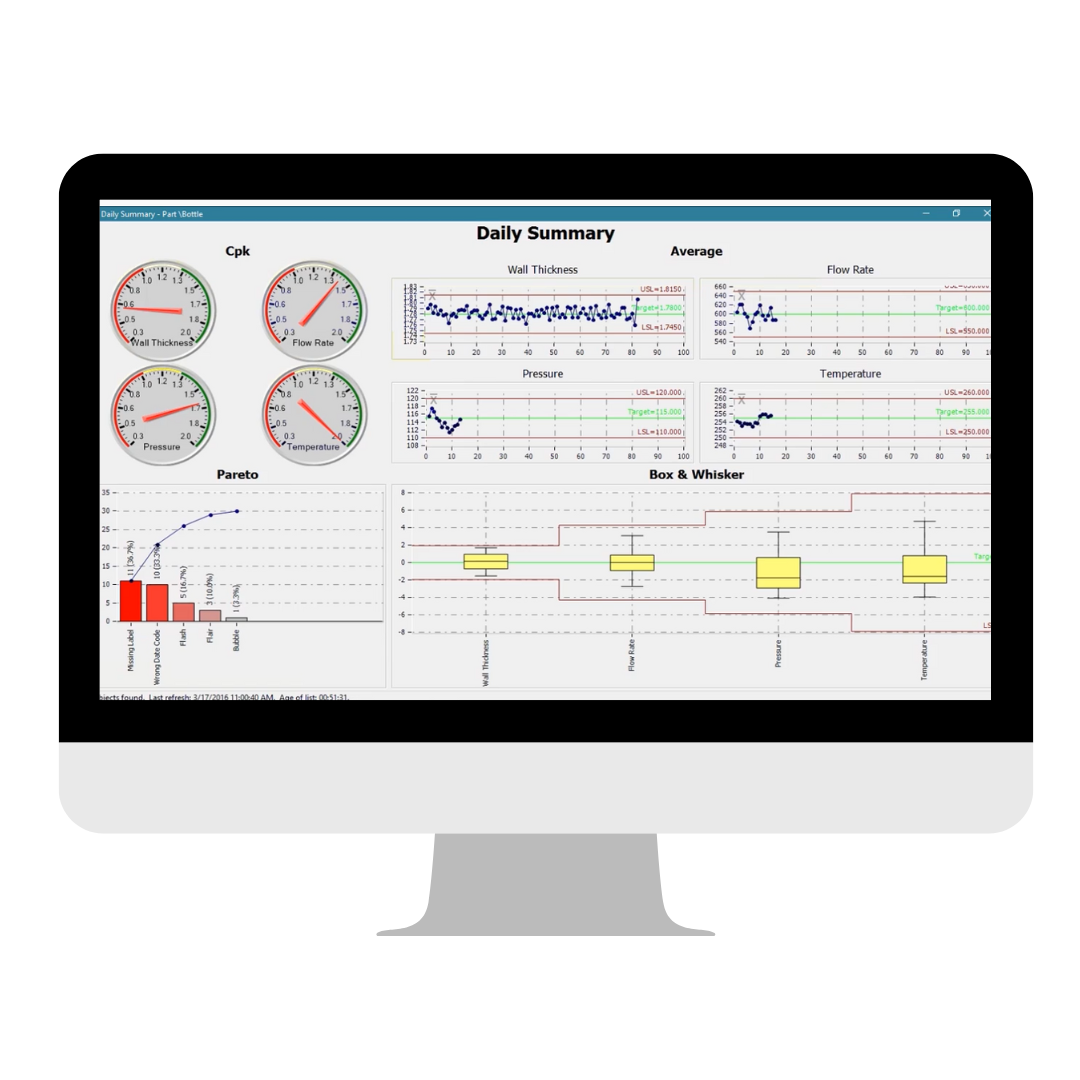

WINSPC is the most powerful, easy-to-use real-time SPC software that builds control charts, Pareto charts, cause-and-effect diagrams, histograms, and more.

In summary, the SPC methodology aims to detect variations in a production process and take the appropriate corrective actions in order to achieve an improvement in the quality of the product.

Improve manufacturing operations with real-time SPC

You probably collect quality data. But how does that data benefit you? With the right Statistical Process Control (SPC) software solution, the data collected can provide actionable insights into process performance and product quality and consistency.

SPC is an industry-accepted practice that can minimize production costs, optimize product quality, and significantly reduce risk, defects, and inconsistencies.

WinSPC® quality solutions, powered by our industry-leading Statistical Process Control (SPC) engine, provide unparalleled visibility and intelligence.

With our solutions, manufacturers gain insight to make data-driven decisions that improve product quality, reduce cost and risk, and meet compliance requirements.

WinSPC enables manufacturers to turn quality from a problem into a competitive advantage.