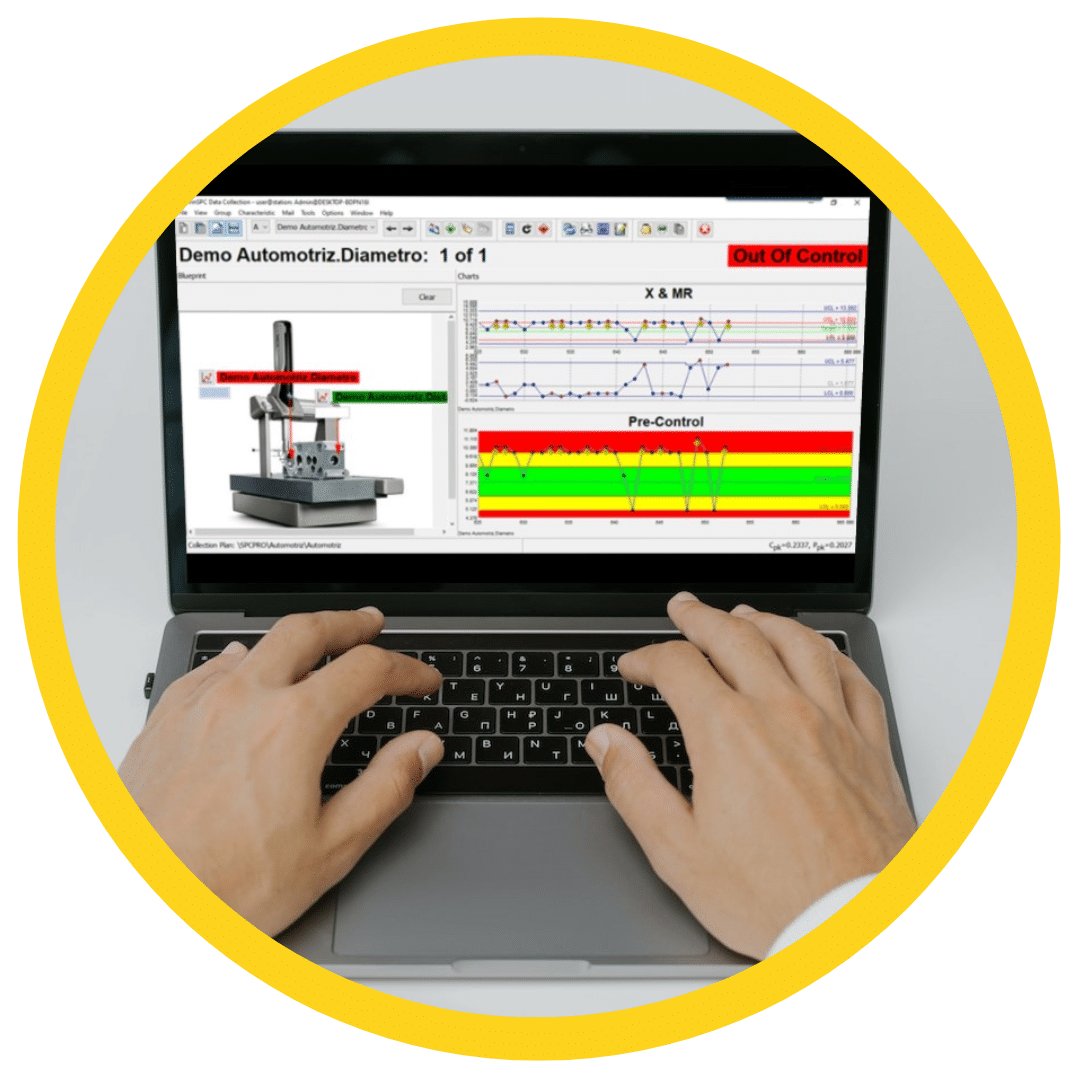

WinSPC

Statistical Process Control Software

Improve the quality of your processes and products in real time

What is WinSPC?

WinSPC is a Real Time Statistical Process Control software for manufacturing companies that want to optimize their processes, with the aim of creating better quality products at a lower cost. Provides real-time statistical information on production processes through plant monitors, control panels / dashboards, alerts, alarms, and personalized reports.

WinSPC allows to have a predictive analysis in Real Time to be able to prevent deviations in production, and thus comply with quality regulatory requirements.

WinSPC allows you to capture data from any information source, such as measuring instruments (calipers, vernier calipers, dial gauges), text files (CMM, Vision Systems), Excel, machines (PLC), databases and external systems (ERP ).

WinSPC Benefits

Better Decision Making

Check production and quality control information for better decision making.

Manufactures with higher quality

Alerts in real time that provide continuity, reduce variation and allow the delivery of higher quality products.

Compliance and guarantee

Develop a competitive advantage and meet the quality standards of the industrial market.

Increase Profitability

It allows the reduction of shrinkage/SCRAP, optimization of resources and guarantees quality at the lowest cost.

Advantages

Ensure quality levels

Reduce defects

Reduce wasted time

Reduce inspection levels

Streamline reporting

Compare results

Reduce audit costs

Eliminate the use of paper

Certifications where

WinSPC makes the difference

ISO 9001:2015

WinSPC contributes to compliance with this standard through:

- Process monitoring and measurement (Requirements 9.1.1)

- Data analysis (Requirement 9.1.2)

- Corrective and preventive actions (Requirement 10.2)

- Continuous improvement (Requirement 10.3)

- Traceability (Requirement 8.5.2)

- Documentation (Requirement 7.5)

IATF 16949:2016

WinSPC contributes to compliance with this standard through:

- Process management (Section 4.4.1)

- Monitoring and measurement (Sect. 9.1.1)

- Corrective and preventive actions (Section 10.2)

- Continuous improvement (Section 10.3)

- Supplier Management (Section 8.4.2.3)

- Traceability (Section 8.5.2)

FDA21

WinSPC contributes to compliance with this standard, specifically in section 21, part 11, in the following subsections:

- Electronic Signatures (Subpart C)

- Electronic Records (Subpart D)

- Access Control (Subpart A and B)

- Data Integrity (Subpart D)

- Audit (Subpart E)

ISO 13485:2016

WinSPC allows compliance with the standard in the following sections:

- Process monitoring and measurement (Section 8.2.3)

- Corrective and preventive actions (Section 8.5.2)

- Process Validation (Section 7.5.2)

- Control of Records (Section 4.2.4)

- Continuous Improvement (Section 10.3)

- Risk Management (Section 7.1)

AS9100:D

WinSPC contributes to compliance with this standard through:

- Continuous monitoring of processes (Requirement 8.5.1)

- Production and service control (Requirement 8.5.2)

- Corrective and preventive actions (Requirement 10.2)

- Continuous improvement (Requirement 10.3)

- Documentation (Requirement 7.5)

- Risk Management (Requirement 8.4.3)

ISO 22000:2018

WinSPC permite el cumplimiento de los siguientes puntos de la norma:

- Monitoreo y control de procesos (Requisito 8.1.3)

- Verificación (Requisito 8.2)

- Acciones correctivas y preventivas (Requisito 10.2)

- Mejora continua (Requisito 10.3)

- Trazabilidad (Requisito 8.5)

- Gestión de riesgos (Requisito 6.1)

Industries that use

WinSPC

Automotive and Transportation

WinSPC enables compliance verification of the parts/products they manufacture to customer specifications, and are often expected to provide regular updates to ensure quality levels are met.

Defense and Aerospace

Storing the resulting data in the central WinSPC system will allow you to easily monitor, supervise and analyze the information for the continuous improvement that your industry needs.

Consumer goods

Many of these products are manufactured in high volumes, making them particularly suitable for a real-time SPC program.

Construction materials

WinSPC enables manufacturers to efficiently produce the highest quality products, while continuously improving the productivity of manufacturing processes.

Plastics and Packaging

Consistent packaging performance, whether it’s a carton, bottles or aluminum cans, is a critical quality element that enables your customers to improve the efficiency of their filling line and minimize downtime due to package defects.

Medical devices

Implementing WinSPC in your production environment allows you to improve product and process control while ensuring compliance with regulatory requirements.

Pharmaceutical

WinSPC can predict and prevent defects during the manufacturing process, through real-time SPC applications that allow instant insight into process variations for correction and control.

Electronics

Interoperability between SPC and other systems, such as ERP and MES, is the key to achieving quality control in complex automated operations.

Food and drinks

WinSPC offers the tools so that your company can automate the collection of weight, temperature and other quality controls, which allow you to control the processes with graphics and alarms in real time.