What is SPC and how does its implementation benefit your business?

For a long time it was believed that it is impossible to manufacture products without variations, which is why manufacturers of all types have used tolerance limits as a basis for determining quality for many years.

That is, they rely on the results of the final inspection to determine whether they comply or not. While in mass production, sampling plans are used that evaluate quality batch by batch.

The problem with these methods is that the variation is not being measured, making it very difficult to correct problems instantly or detect the causes thoroughly.

Fortunately, there is a methodology that your manufacturing company can use to ensure quality control of its production processes, regardless of the industry to which it belongs.

Statistical process control, better known as SPC, is a method of measuring and controlling quality through detailed monitoring of the manufacturing process.

Through which constant measurement of product performance can be obtained, which is essential for companies that need to guarantee high levels of quality in their products.

Why use SPC?

Globalization has led the manufacturing industry to face increasing competition, while the costs of raw materials continue to rise or there are even shortages of them, as a result of the pandemic.

This has forced companies to focus on continuous improvement, efficiency and cost reduction.

In addition, more and more industries require the implementation of SPC, as its use is mandatory in certifications for the manufacture of automotive parts (IATF 16949, VDA), semiconductors, aerospace (AS13006) and medical devices, among others.

However, to obtain the benefits of the SPC method, it must be implemented in real time and this requires the use of software such as WinSPC.

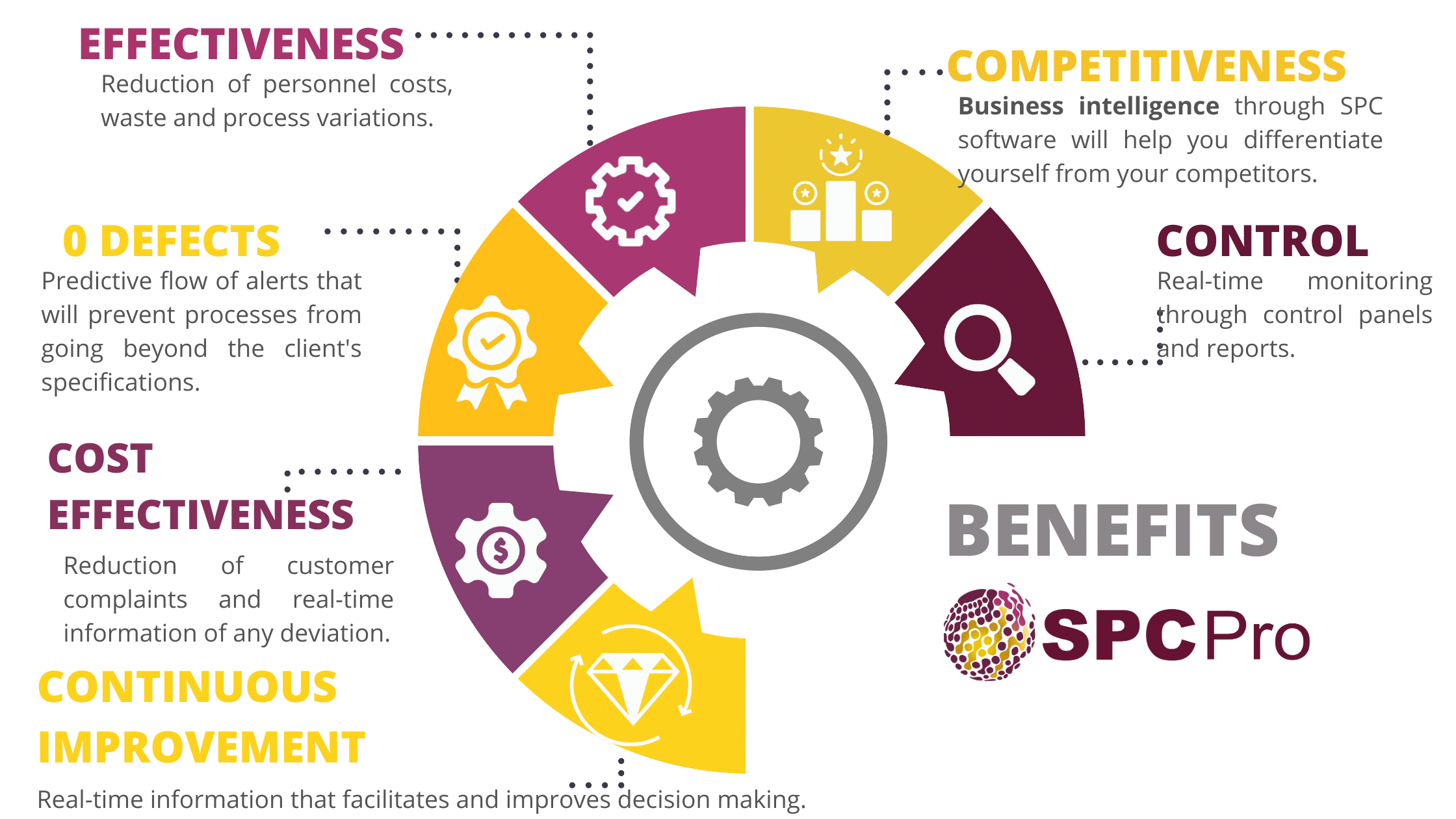

Benefits of implementing SPC in real time

Control

It is very important to know both when a process is running properly and when it has failures, since, sometimes, trying to detect if a problem exists can generate variations that ultimately become failures.

Control charts can reveal what is happening on a production line in real time, allowing errors to be detected and corrected before a major impact occurs on the product line.

Effectiveness

A lot of money and resources are wasted when products are not manufactured correctly. An SPC solution is a powerful tool to control production costs, by monitoring the quality of products, defects can be detected before product delivery, which reduces rework costs.

With an SPC system you can obtain graphs that show all the statistical data necessary to monitor production efficiency. Statistical data shows immediate analysis for process improvement and timely detection of defects.

0 Defects

In a production process the ideal objective would be to achieve maximum uniformity, which although not always possible, the higher the percentage achieved, the lower the amount of waste, rework and customer dissatisfaction.

Having SPC software ensures a high degree of consistency in the final product, regardless of the number of units produced, which helps minimize the need to rework a product or the additional costs incurred by returning the product.

Cost effectiveness

With an SPC solution it is easier to create better products, with a lower percentage of failures or damages, increasing customer satisfaction, while reducing waste and costs, which translates into greater profits for your business.

By optimizing processes and reducing variations, it is possible to guarantee that each part that leaves an assembly team rigorously meets customer specifications.

Continuous improvement

With traditional quality controls, it is difficult to identify a problem during the manufacturing process, but with an SPC solution all defects can be detected during the production process facilitating a continuous uninterrupted workflow.

Data analysis can provide greater visibility to standards in the design and creation of products, which can become a process of continuous improvement, benefiting cost savings, raw material efficiency and production optimization. .

Business Intelligence

Without reliable data, the decisions of operators, engineers and managers often tend to be based on their experience or instinct.

On the other hand, having control charts validates the veracity of the data and eliminates myths about the processes. When all staff have access to the same data, decision making will be better at all levels of the organization.

Business intelligence through SPC software will help you differentiate yourself from your competitors and facilitate the way you address your quality challenges.

Obtaining real-time information about production quality control processes is essential to avoid unexpected costs as a result of process failures and product quality problems.

An SPC solution will be present in all parts of the production process because it helps reduce waste, defects and rework, improves product quality, eliminates process variation and maintains compliance with customer requirements and specifications.

However, to obtain the benefits of SPC, it must be implemented in real time and this requires the use of software such as WinSPC.

Written by Juan Olano

Success story: Denso automates quality inspection with WinSPC

DENSO is a global company focused on advanced mobility that positively changes the way the world moves and contributes to well-being. As a global Fortune 500 company, we have a broad product portfolio and global impact.BackgroundDenso is a premier automotive supplier,...

WinSPC version 9.0.14

WinSPC is an advanced software for Statistical Process Control in real time, which allows leading industries in the market to monitor and optimize their production processes, to improve the quality of their products, reduce the variation in processes and increase the...

Success story: Denso automates quality inspection with WinSPC

DENSO is a global company focused on advanced mobility that positively changes the way the world moves and contributes to well-being. As a global Fortune 500 company, we have a broad product portfolio and global impact.BackgroundDenso is a premier automotive supplier,...

Subscribe to the Blog

To stay up to date with all the news and exclusive content

Recent Comments